Produits, solutions et services pour les entreprises

Industry 4.0 — aka the Fourth Industrial Revolution — enables the transformation of factories into smart and sustainable manufacturing facilities. Industry 4.0 encompasses the Industrial Internet of Things (IIoT), Artificial Intelligence (AI) and Machine Learning (ML), cloud computing, and cybersecurity. Smart manufacturing leads to improved production, operating margins, and quality, while reducing waste and energy consumption. Industry 4.0 requires an all-optical network, capable of moving and managing data quickly, between machines, across factory floors, to control rooms, to the edge, and to the cloud. A Passive Optical LAN (POL) realizes Fiber To The Machine (FTTM), enabling fast, reliable, and secure communications across long-production lines and within harsh manufacturing environments.

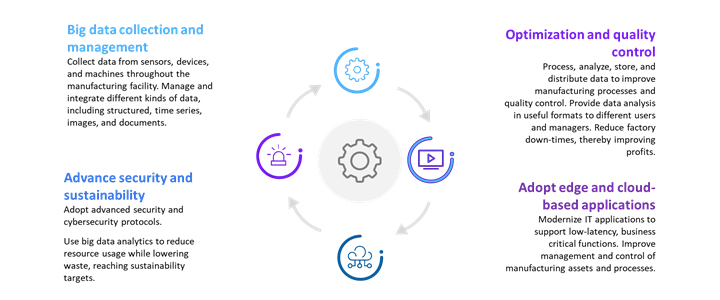

Factories have advanced since the First Industrial Revolution in the 18th century and the subsequent adoption of Programmable Logic Controllers (PLCs). The next major step to be taken is the move to Industry 4.0, increasing efficiency and output while adopting sustainability or green factory goals. Industry 4.0 transforms data into intelligent insights and tangible benefits, such as increasing equipment efficiencies, automating inventory management, improving quality, lowering energy usage, and reducing waste. Figure 1 summarizes the key components of a smart, sustainable factory.

Figure 1: Key components of a smart, sustainable factory

Source: Omdia

Industry 4.0 requires a seamless communications network, connecting factory-floor machines, software applications, data storage containers, and edge computing. Massive volumes of data must be integrated, processed, and analyzed. Edge computing requires a low-latency communications network to support business-critical processes and applications. The underlying communications network must be fast, secure, reliable, and immune to factory-floor environmental conditions. Wireless networks are part of the solution, but wireless is not sufficiently fast, reliable, or robust in large factories and harsh environments. Optical networking meets the requirements for Industry 4.0.

Fiber connectivity, or all-optical, is becoming the backbone for Industry 4.0, supporting massive numbers of time-sensitive, low-latency connections and interconnections between machines and industrial processes. Within an all-optical infrastructure, FTTM is a key component, supporting machine vision and AI quality inspection, along with low-latency data analytics for manufacturing control and management.

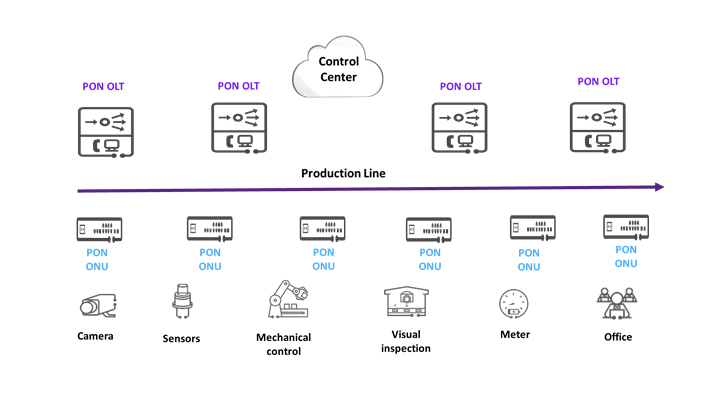

POL technology is based on passive (non-powered) splitters, which is critical within a factory facility. Fiber does not decay from contact with oil or grease, and it is immune from electromagnetic interference. In addition, all-optical networks support communications across large production lines and across large manufacturing sites. Figure 2 illustrates an all-optical smart factory scenario with POL.

Figure 2: A POL uses PON (OLT and ONU) equipment: a smart factory scenario

Source: Omdia

An all-optical network provides key advantages compared to copper and wireless technologies. While wireless technologies can support some machine-to-machine communications, they are not sufficiently robust to handle low-latency, cloud-based data analysis and control. In addition, wireless technologies often encounter interference issues in manufacturing facilities.

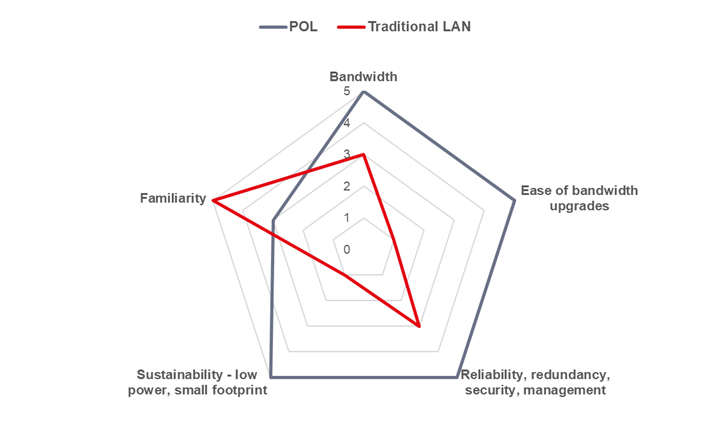

A traditional copper-based Local Area Network (LAN) consists of switches and routers, where devices are connected using Cat5 or Cat6 cables. Figure 3 compares POL's advantages to a non-optical LAN.

Figure 3: POL versus LAN for Industry 4.0

Source: Omdia

One of the key advantages of a fiber-optics-based POL concerns bandwidth. Most twisted pair Ethernet cables support 100 Mbit/s, while some support up to 1G . Passive Optical Network (PON)-based POLs support symmetrical bandwidths up to 10G and, in the near future, 50G . In addition, the upgrade process is simple since the same fiber optics cabling is used.

The POL approach enables significant savings in both Capital Expenditure (CAPEX) and Operational Expenditure (OPEX). An optical LAN — a POL — uses less cabling and fewer racks and switches than a traditional LAN. The passive network in a POL saves energy, with less power and cooling needed. In addition, optical cabling is often smaller than Cat5 or Cat6 cabling, thereby reducing the amount of physical space needed for the cabling. A POL network can easily cover a 20 km or even 40 km campus.

POLs are based on carrier-grade five nines reliability — 99.999% — PON equipment. The underlying network can be designed to provide redundancy if determined necessary. Optical fiber is immune to electromagnetic interference, radio frequency, and electromagnetic pulses. PON networks are considered highly secure. They are difficult to tamper with and even meet the security requirements of defense agencies.

The largest issue facing the adoption of optical-based LANs is around familiarity. Optical networking is still relatively new compared to traditional LANs. The case studies provide an overview of the use of optical networking to achieve Industry 4.0 and a smart manufacturing facility.

BYD Co. Ltd.— with BYD standing for Build Your Dreams — is a publicly-listed Chinese manufacturing company. BYD is a major manufacturer of automobiles, buses, and trucks. In April 2022, BYD ceased production of fossil fuel-powered vehicles, turning its manufacturing resources to pure electric and plug-in hybrid electric vehicles. The company began mass production of electric vehicles in 2008 and reached the one-million electric vehicle milestone in 2021. Optical communications networking has played an important role in BYD’s smart manufacturing goals. It is using optical communications with a POL, enabling high-speed, low latency connections on its very long production lines. For BYD, a POL reduced cabling costs by 50% compared to traditional copper cabling. And power consumption was reduced by more than 40% given a POL's passive networking attributes and efficient network topology. Luo Xiaoping, Manager of the Communications and Information Security Department of BYD's Information Center, commented:

"BYD built an industrial cloud platform to ensure efficient and high-quality production. The new communications architecture encompasses data centers as the computing center, enabling intelligent management and control of end devices. The communications network must support fast rollout, high reliability, and flexibility. Traditional networks cannot meet these requirements. We chose a POL, using fiber as the transmission medium. A POL supports BYD’s strategy of 'Technology • Green • Tomorrow.'"

Shaanxi Fast Auto Drive Group (Fast Group) is one of China’s largest manufacturers of automatic transmissions for heavy-duty vehicles. The company adopted a POL to improve production and quality control throughout its large manufacturing facilities. This POL is now providing the necessary bandwidth to collect large amounts of data throughout manufacturing processes, then perform edge and cloud-based analytics — quickly, reliably, and securely. Fast Group attributes increased production and higher operating profit margins to its adoption of Industry 4.0, with a POL cast as the integral communications and networking solution.

All-optical communications networking is being adopted by manufacturers around the world, providing secure, highly-reliable broadband communications. All-optical supports AI, the machine-to-machine Internet of Things (IoT), remote vision and control, and data analytics, all leading to improved manufacturing processes, efficiencies, and quality control. All-optical networking performs within the harsh environment of manufacturing facilities, without impact from chemicals, vibrations, or temperatures.

Within all-optical, a POL is a key enabler for Industry 4.0 and software-defined manufacturing, integrating new communications technologies, while reducing network complexities and energy usage. A POL provides manufacturing facilities with a reliable and robust, fiber-based broadband communications network for use throughout the manufacturing facility, encompassing machine-to-machine, machine to operators, and all company teams and divisions.

Manufacturers should study POL technology to understand the capabilities for Industry 4.0 and software-defined manufacturing.

Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the official policy, position, products, and technologies of Huawei Technologies Co., Ltd. If you need to learn more about the products and technologies of Huawei Technologies Co., Ltd., please visit our website at e.huawei.com or contact us.