Today, the digital economy is the new driving force for both enterprise and social development, changing all aspects of society, including production, work, life, and governance. As such, data resources, carried by modern information networks, are now key.

In this regard, the energy industry is no exception and it has seen significant changes to its production, supply, sales, and storage processes. Technologies like 5G, Artificial Intelligence (AI), quantum computing, blockchain, and the industrial Internet are now accelerating the construction of intelligent energy infrastructure, including power plants, grids, and the energy Internet. Such infrastructure, in turn, promotes intelligent energy processes, upgrading energy production, storage, transmission, and consumption. And all of this enables low-carbon, digital, and intelligent transformation.

China's policies call for clean, low-carbon, safe, and efficient energy systems. They point to new energy production, shifting away from coal and quickly developing clean, low-carbon energy sources. The way we consume energy will therefore also change, using new types of power systems where generation, grids, load, and storage all interact with each other, and multiple types of energy complement the supply. To achieve China's 2030 carbon peak and 2060 carbon neutrality targets, the industry is developing wind, Photovoltaic (PV), and other new energy systems on a large scale. As a result, traditional thermal power will eventually no longer represent the main power supply, but will only be used for peak-load regulation and backup.

Amid this transition, power generation enterprises are facing several challenges. They need to adjust their energy structure, collaborate with new industry chains, rebuild the use of thermal power, and comprehensively manage carbon assets. To succeed, they need to capitalize on the opportunities these challenges present. This means actively participating in building up new power systems and digitalizing enterprises, integrating digital technologies into business scenarios to enable intelligent operations, data-driven decision-making, and more precise services.

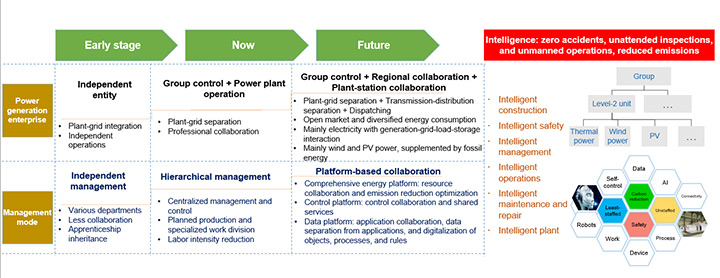

The State-owned Assets Supervision and Administration Commission of the State Council (SASAC) has put forward requirements for digital product innovation, intelligent production and operations, agile user services, and ecological industrial systems. Safe, efficient, green, and digital business systems benefit power generation companies and increase intrinsic safety. The entire industry chain can collaborate using intelligent applications for construction, safety, management, repairs, operations, and campuses. This chain includes raw material production, procurement, transportation, storage, power generation, and market sales. Intelligent applications can also help monitor, diagnose, analyze, and report alarms in real time, providing feedback regarding onsite personnel and device statuses. This allows companies to measure, trace, and monitor the entire energy process. Power plants become intelligent as a result, with zero accidents, unattended inspection, and unmanned operations, all of which reduce emissions, as shown in Figure 1.

Figure 1: The digital evolution of power generation enterprises

During the 13th Five Year Plan (2016–2020), China made great achievements promoting digital industrialization and industrial digitalization. Indeed, the country has quickly integrated digital technologies with businesses, improving the digitalization of the production equipment of industrial enterprises. However, some challenges persist. There is still a digital divide between different industries, regions, groups, and services. In addition, despite the wealth of data, its value is not always unleashed. And there is still room for improvement in digital systems and standards.

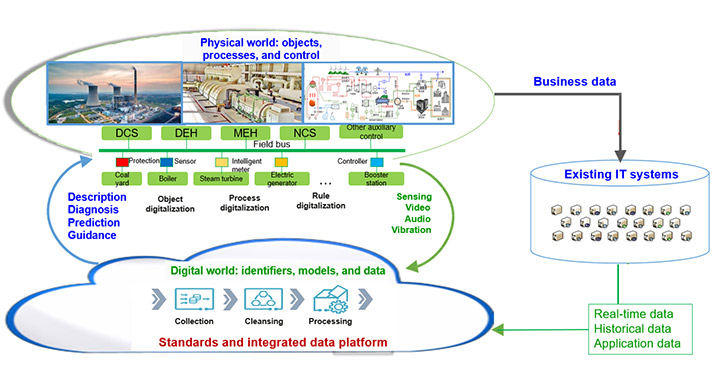

This is also true in the field of power generation. It is still difficult to utilize equipment, operations, and management data. Business systems are isolated from each other and the digital divide is growing. That's why there are many opportunities in the ongoing industrial revolution. Using data elements as the core engine for growth, we need to break the traditional boundaries between data and systems. This means we also need more unified standards and data platforms. At the same time, data needs to be separated from applications, which will help stimulate the value of data from objects, processes, and rules, as shown in Figure 2.

Figure 2: An integrated data platform where data and applications are separated

Today, there are over 20 billion Internet of Things (IoT) devices around the world. If each device has 10 measurement points and each point collects 10 data items, 2 trillion data items will be generated every second. That's a massive amount of data. If we take data as a factor of production and improve its efficiency by just 1%, we'd be generating an added value worth US$66 billion. However, if data is not deeply mined and utilized, it generates no value. Some enterprises remain stagnant and fail to change with the times, which slows down digital transformation. Power plants are asset-heavy, home to a wealth of production equipment, and also employ a lot of operational staff. They produce lots of crucial operational data, which can have a meaningful impact if properly utilized.

Hierarchical data governance is urgent if power plants want to revitalize the massive data they produce. The organizational structure of power generation enterprises in China can be divided into three levels: group, level-two unit, and power plant. In the future, these enterprises will need to build many complex systems for wind power, PV, and multi-energy complementation. They will also need to allocate thermal power and new energy as needed, along with managing all their carbon assets. To facilitate these processes, it is important to standardize both the technical and business architectures plus the processes and data of each power plant. In particular, data should be centrally scheduled and managed. For this, power generation enterprises need to build a hierarchical data governance system to support sustainable development.

Power generation enterprises have a large number of business systems, ranging from dozens to hundreds. However, there is rarely a top-level design to centralize these systems, and data is managed using different attributes. Therefore, data scattered among business systems, power plants, and groups should be aggregated and shared to converge data management, analysis, and mining across systems and layers.

A further problem is information silos, which prevent global management and control, particularly because different applications use different data formats. Without a single standard, compatibility and database interconnection are difficult, meaning that data cannot be exchanged. Furthermore, many companies prefer not to share information resources and worry about data security. An integrated data platform is necessary to aggregate all data and information as well as integrate data into a data lake. It would also break the data silos caused by independent system construction, device Operations and Maintenance (O&M), and department management, establishing an interconnected data environment.

Such a platform facilitates flexible data application, intelligent interaction among business systems, and application innovation. It helps build data assets, stimulating data value and making power plants smarter.

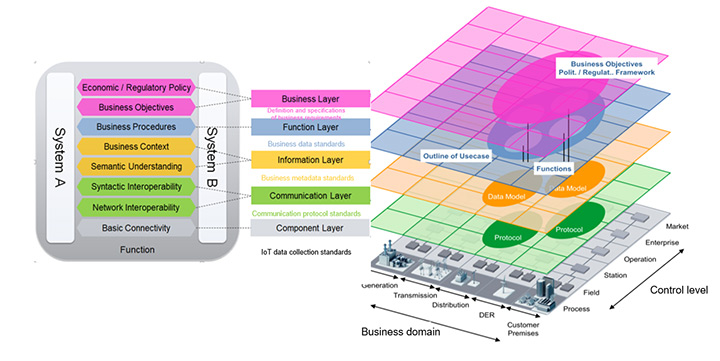

Building integrated technical architecture and data standards allows all functional layers to run in a single system. As shown in Figure 3, relevant standards need to be formulated first to then establish cross-layer and cross-domain technical architecture. Having eliminated information silos and data barriers, data continuity is ensured. This means that data services can be reused, reducing the development and deployment costs of new functions, providing a sound digital basis for business expansion.

Figure 3: Technical architecture of data layering and interoperability

Data is critical for future development. Power generation enterprises need resilient and flexible systems, interconnected intelligent infrastructure, and new integration platforms to develop data-centric operations, mine more value from data, and support the evolution and upgrade of business models. In the foreseeable future, modern energy systems will embrace a brand-new digital ecosystem. At the same time, integrated platforms will stimulate data value while enabling low-carbon and efficient business.

Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the official policy, position, products, and technologies of Huawei Technologies Co., Ltd. If you need to learn more about the products and technologies of Huawei Technologies Co., Ltd., please visit our website at e.huawei.com or contact us.