Wi-Fi 6 Advanced: A Great Fit for Enterprises to Build Speedy, Stable, and Smart Wireless Production Networks

Enterprises of all sizes around the world are increasingly aware of the importance of Digital Transformation (DX), believing that the key to achieving DX goals is network quality. For this reason, a reliable, secure, and efficient wireless network is of paramount importance for enterprises to develop their digital business.

As the main wireless connection mode within enterprises, Wi-Fi has already played a positive role in the digital transformation of enterprises. Since Wi-Fi 6 was first put into commercial use, three years ago, this latest generation of Wi-Fi has been developing at breakneck speed. According to global market intelligence firm, the International Data Corporation (IDC), global enterprise-class Wi-Fi 6 shipments exceeded 5.5 million units in 2020, up 366% from the previous year. This figure is expected to surpass 41 million by 2025.

Indeed, Wi-Fi 6 is reshaping all industries and has proven highly valuable in office scenarios. In the manufacturing and energy industries, however, Wi-Fi 6 is unable to completely resolve every technical difficulty, including ultra-high reliability, ultra-high performance, Internet of Things (IoT) convergence, and edge control.

"Wireless is an important means for enterprise digital transformation," said Dr. Li Xing, President of the Campus Network Domain for Huawei's Data Communication Product Line. "With this in mind, Huawei launched its Wi-Fi 6 Advanced Solution, which is designed to build speedy, stable, and smart wireless networks. This innovative solution extends Wi-Fi 6 from workplaces to production environments, enabling flexible production, unstaffed factories, and little-staffed production lines."

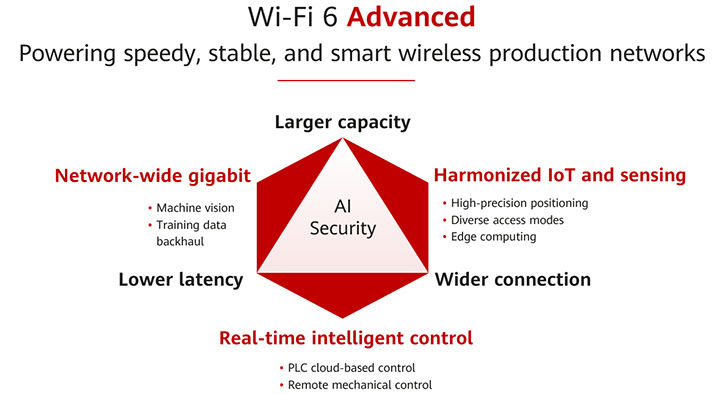

Wi-Fi 6 is known for its large capacity, low latency, and wide connections. Going beyond these, the Wi-Fi 6 Advanced Solution takes on three new characteristics, with Artificial Intelligence (AI) and security at the core: network-wide gigabit connections, real-time intelligent control, and harmonized IoT and sensing.

- Network-wide gigabit connections: The Wi-Fi 6 Advanced Solution stands out by supporting Wi-Fi 6 Extended (Wi-Fi 6E), an extension of Wi-Fi 6 that adds the 6 GHz frequency band to offer up to seven additional 160 MHz channels. In this way, Wi-Fi 6E devices can easily deliver gigabit wireless access everywhere, sometimes styled as "gigabit wireless @ everywhere." In addition, a new dynamic-zoom Smart Antenna supports both omnidirectional and high-density coverage modes. This one-of-a-kind antenna improves wireless performance at the edge, by 20% in high-density coverage mode. Plus, innovative Coordinated Spatial Reuse (CoSR) technology enhances wireless performance by 15%, and Fluent-Multiple-Input and Multiple-Output (Fluent-MIMO) technology increases concurrency speeds by 20%.

- Real-time intelligent control: With this new solution, Huawei has unveiled three innovative technologies — air interface slicing, dual-fed and selective receiving, and lossless roaming — to deliver highly reliable and low-latency network assurance for real-time services. Specifically, air interface slicing offers 99.999% reliability and ultra-low 10 ms latency for periodic services, ensuring a deterministic experience. Meanwhile, dual-fed and selective receiving also achieve 99.999% reliability, while lossless roaming ensures zero packet loss for services and accelerates rapid handover to within 10 ms.

- Harmonized IoT and sensing: In production environments, disparate IoT systems coexist and can't easily communicate with each other. To address this issue, Huawei has launched its Wi-Fi and IoT Convergence Solution, which supports a wide range of IoT technologies — such as Bluetooth, Radio Frequency Identification (RFID), and ZigBee — by using built-in IoT slots, external IoT Universal Serial Bus (USB) ports, and built-in IoT chips. Huawei AirEngine Wi-Fi 6 Access Points (APs) also support Software-Defined IoT (SD-IoT) and are embedded with containers to offer an array of open interfaces. These capabilities make it easy to implement third-party applications on demand, as well as detect IoT terminal status and quickly handle data at the edge. Additionally, Huawei has developed the iConnect protocol, which involves many functional modules, such as access and authentication. With iConnect, the network can automatically discover and accurately identify various kinds of IoT terminals, as well as enable them to access wireless networks securely and seamlessly.

The Huawei Wi-Fi 6 Advanced Solution also integrates AI capabilities into Wi-Fi technologies at scale. For example, Huawei's intelligent radio calibration technology analyzes historical network quality through big data analytics and then performs predictive optimization, across the entire network. The end result is over 50% higher network performance.

Conventional radio calibration focuses only on APs and ignores the actual terminal experience, resulting in unsatisfactory calibration results. Huawei overcomes this with the industry's only 3D radio calibration algorithm, centered on the terminal experience. This algorithm enables AI-powered 3D scenario identification and 3D radio calibration, thereby achieving network-wide optimization and improving network performance by over 20%.

AI roaming, another stand-out innovation, customizes differentiated roaming steering policies for each terminal. This ensures that each terminal can be proactively steered to the optimal AP, at the optimal time, ultimately increasing the link speed for roaming terminals by 30% and boosting the roaming success rate by 70%.

Huawei Wi-Fi 6 Advanced is a good fit for various production scenarios, from production lines in the manufacturing industry to mines in the energy industry and the Internet of Medical Things (IoMT) in healthcare. It's worth exploring these typical use cases in more detail.

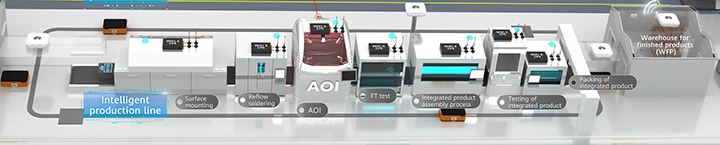

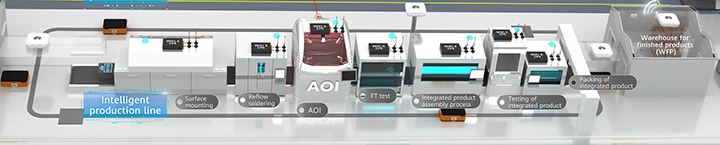

Production lines in the manufacturing industry

The key to smart manufacturing is to make production lines fully wireless, including services such as Automated Optical Inspection (AOI), Programmable Logic Controller (PLC) control, Automated Guided Vehicles (AGVs), and asset management. This helps make flexible factories a reality, reducing costs and improving efficiency.

- AOI: Ultra-large bandwidth is required by AOI operations, including capturing product images, uploading them to the server, and automatically inspecting product quality through AI. Huawei's Wi-Fi 6E APs and Wi-Fi 6E Customer-Premises Equipment (CPE), combined with CoSR technology, offer the ultra-high gigabit wireless bandwidth needed for AOI tasks on production lines.

- PLC control: Devices such as robotic arms are PLC-controlled, in order to automatically produce products. When servers deliver task instructions and collect information, ultra-high reliability is required to ensure production services. Huawei achieves this by using air interface slicing as well as dual-fed and selective receiving technologies. Specifically, link-level protection through dual radios achieves high reliability of 99.999% and ultra-low latency of 10 ms, effectively implementing periodic task scheduling.

- AGV and asset management: AGVs are indispensable for automatically transporting raw materials and finished products. When they are moving, services must experience zero packet loss. Huawei's lossless roaming technology does just this by ensuring zero service interruptions for AGV scheduling, anytime, anywhere. For asset management, products and materials need to be conveniently managed through IoT applications. Huawei's Wi-Fi and IoT convergence technology monitors material and product locations in real time, facilitating inbound, outbound, and inventory management. Furthermore, Wi-Fi and IoT convergence slashes the Total Cost of Ownership (TCO) by 50%.

Huawei Wi-Fi 6 Advanced allows production lines to go fully wireless, paving the way for flexible production. For example, a mobile phone manufacturing enterprise has 300 production lines. To keep up with constantly evolving mobile phone models, the enterprise has to change these production lines at least once every quarter. Traditionally, production lines have mainly used wired connections and consequently have had to be suspended for at least three days for each production line change. With Huawei Wi-Fi 6 Advanced, production lines can now go fully wireless, slashing the production line suspension time to less than half a day. For our hypothetical mobile phone enterprise, this equates to 12 million more mobile phones produced over the course of a year.

In short, Huawei Wi-Fi 6 Advanced helps lead the manufacturing industry into the flexible production era, ushering in lower costs, higher efficiency, and better quality.

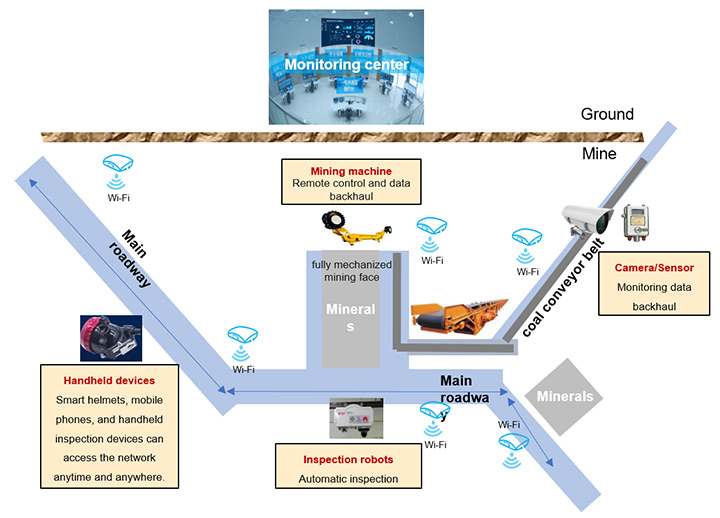

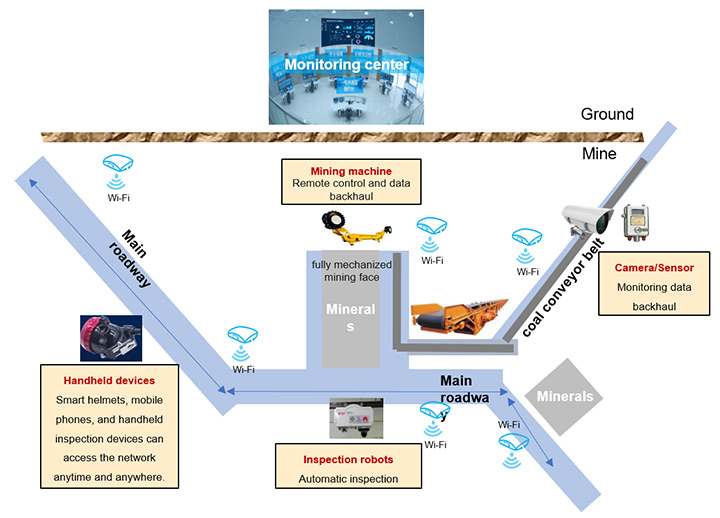

Mines in the energy industry

Today, mines are undergoing digital transformation and evolving toward little-staffed or even unstaffed. Networks need to be continually deployed as mining excavation progresses, which is why wireless is widely recognized as the best network solution for mines. Indeed, wireless brings an all-new experience to mining machines, inspection robots, handheld devices, cameras, sensors, and other facilities in typical mining scenarios.

- Mining machines: To enjoy a safer and more efficient work environment, ground workers yearn for remote operations for mining machines. Obviously, they also need the network to deliver high reliability and low latency. Huawei ticks both of these boxes with its dual-fed and selective receiving technology, which offers link-level protection through dual radios, achieving high reliability of 99.999% and ultra-low latency of 10 ms. The end result is mining machines that can be operated remotely and in real time.

- Cameras and Sensors: Typical mines use cameras and sensors to monitor the underground environment and production process, improving production security. This needs a network that can offer high concurrency capabilities. Huawei's Wi-Fi 6E and Fluent-MIMO technologies enable ultra-high concurrency for both cameras and sensors. Going further, Huawei's Wi-Fi and IoT convergence technology facilitates unified access of various sensors, such as gas density sensors, to the wireless network. This allows videos and sensor data to be rapidly transmitted to the control center, protecting the safety of miners and entire mines.

- Inspection robots and handheld devices: Inspection robots need to perform inspection in tunnels at all times, to immediately detect potential safety risks. In addition, the handheld devices of miners typically enable monitoring and communications services that also help improve production efficiency and safety. The common thread here is that they all need the network to have zero service interruptions, supporting uninterrupted mobility. This is where Huawei's lossless roaming and fully wireless networking technologies come into their own. Using these technologies, inspection robots can send mine status data, and handheld devices can transmit monitoring data, all to the control center, rapidly and losslessly. In turn, this helps ensure the safety of miners and, once more, entire mines.

With Huawei Wi-Fi 6 Advanced, mines become little-staffed or even unstaffed and benefit from lower costs, higher efficiency, and maximal production safety.

IoMT

Medical devices in the healthcare system are expensive and therefore must be used as efficiently as possible. Other priorities include improving the efficiency of patient care while reducing the workload of healthcare workers. Stating it simply, all such goals can be realized by building an IoMT network that integrates Wi-Fi and IoT.

- Large medical devices: Computerized Tomography (CT), Magnetic Resonance Imaging (MRI), and Digital Subtraction Angiography (DSA) all require high bandwidth for data transmission. Huawei's Wi-Fi 6E APs and Wi-Fi 6E CPE, combined with CoSR technology, offer the ultra-high gigabit wireless bandwidth needed for such medical devices.

- Intensive Care Unit (ICU) monitoring equipment: Ventilators and Electrocardiogram (ECG) monitors are often moved between different wards or used on the go. To improve the efficiency of their use, going wireless is a must and services simply must not be interrupted while mobile. To this end, Huawei's Wi-Fi 6 CPE transforms wired into wireless access. Plus, Huawei's lossless roaming technology ensures no interruptions to mobile services.

- Mobile monitoring, asset management, and medical waste management: IoT terminals, such as positioning wristbands, infusion monitors, and ECG wearables are popular ways to improve the efficiency of patient care. Huawei's Wi-Fi and IoT convergence technology enables such IoT terminals to easily access the converged IoT and Wi-Fi network. In addition, IoT and Wi-Fi convergence slashes TCO by 50%.

Huawei Wi-Fi 6 Advanced greatly improves the efficiency of medical resource use as well as increasing individual medical workers' efficiency.

In summary, Wi-Fi 6 brings a fully-wireless office experience to enterprises, while Wi-Fi 6 Advanced goes a step further by extending Wi-Fi 6 to industrial production. This is made possible through Huawei's extensive range of innovative technologies and products, which effectively meet the demanding needs of production networks while further improving the fully wireless office experience.

Looking ahead, Huawei will continue to develop even more Wi-Fi 6 Advanced use cases together with all industry stakeholders, in order to help enterprises benefit from speedy, stable, and smart wireless production and office networks. Doing so, Huawei will continue to promote the digital transformation of industries, in turn improving the operating efficiency of society at large. And that's good for everyone.

Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the official policy, position, products, and technologies of Huawei Technologies Co., Ltd. If you need to learn more about the products and technologies of Huawei Technologies Co., Ltd., please visit our website at e.huawei.com or contact us.