Productos, soluciones and servicios para los negocios

"No advanced economy can prosper without a strong, innovative manufacturing sector," argues Vaclav Smil in his book Made in the USA: The Rise and Retreat of American Manufacturing.

To some degree, this notion has been echoed by major manufacturing powers. Germany is driving its Industrie 4.0 initiative, China is implementing Made in China 2025, and the US is working on the Industrial Internet. These national manufacturing strategies may differ in names but are the same in essence: applying next-generation Information and Communications Technologies (ICT) and Operation Technologies (OT) to enable smart manufacturing.

Amid this evolution, Huawei's Manufacturing BU has been accelerating the integration of ICT and OT to advance smart manufacturing and innovative development.

In most countries, manufacturing represents a major sector in the national economy. This is especially true for China — the "world's factory" and a burgeoning manufacturing power — that produces 70% of the world's mobile phones, 80% of air conditioners, and 91% of personal computers. The country has a comprehensive industrial system that covers 41 industrial classes, 191 categories, and 525 sub-categories.

To maintain its leading position as a manufacturing power, China must digitalize and enhance the quality of its manufacturing sector. Going digital is not only necessary for economic development, but also key to building a modern economic system and shaping global industrial competitiveness.

Next-generation information technologies are now more widespread than ever; especially popular since the COVID-19 pandemic are digital applications like mobile office, videoconferencing, and remote collaboration. These are propelling the digital transformation of China's manufacturing sector.

From a global perspective, major manufacturing powers are formulating strategies and implementing a profound integration between ICT and OT. This is driven both by internal strategic decisions and the rapid evolution of relevant technologies.

In traditional manufacturing, ICT and OT were developed separately and rarely integrated. However, separately operating OT and ICT networks can result in tremendous security risks and deprive manufacturers of the technical foundation for digital transformation.

As digitalization normalizes, it is finally possible to integrate ICT and OT through technologies like the Internet of Things (IoT), big data, and cloud intelligence. Sensors — key devices in the OT domain — collect data and upload it to the cloud center. The cloud center is part of the ICT domain; it enables big data analytics and a wealth of innovative applications. For today's manufacturers, ICT and OT integration is strategically necessary to reduce costs and increase competitiveness.

How does this integration relate to smart manufacturing?

The main link is data — the key driver of smart manufacturing. Data is at the core of digitalization, which, in turn, lays the foundation for intelligent operations. Since OT and ICT integration facilitates data collection, it is a necessary condition for the digital transformation of the manufacturing sector.

Of course, applying the latest technologies to real-life scenarios is also crucial. How can we replicate best practices in specific scenarios and expand their impact on smart manufacturing? This is a challenge for the entire manufacturing sector and a question that Huawei is now trying to answer.

Since its foundation, Huawei has essentially been a manufacturing enterprise. Every year, we produce millions of mobile base stations, switches, optical communications devices, mobile phones, and tablets for hundreds of telecom operators, thousands of enterprises, and millions of consumers.

As a result, we know first-hand the various challenges a manufacturer faces along the different stages of its digital journey. This gives us unique manufacturing industry know-how and transformation experience. Every time we face a challenge during our own digital transformation, we learn lessons on how to increase operational efficiency while ensuring quality.

Our first-hand experience is a strategic choice. Over time, Huawei has honed its understanding and practical experience in smart manufacturing. Today, we have a portfolio of best practices that have enabled our production and supply processes to become automated, information-based, networked, and digital.

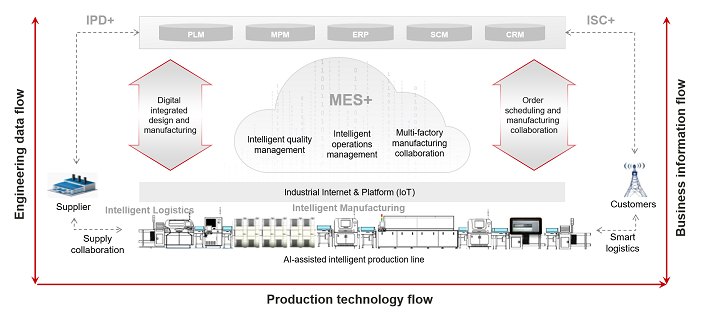

At the core of our best practices are three value streams and one cloud.

To develop our three value streams, we consulted Germany's Reference Architecture Model Industrie 4.0. Our production and supply system highlights integration along the three value streams: engineering data, production process, and business information. Lean management is the basis of our approach. We then use advanced technologies, such as IoT and 5G, to connect resources across the entire value chain, and dynamically manage them using cloud computing, big data, and Artificial Intelligence (AI). Cloud is at the center of the framework formed by the three value streams — it enables the deep integration of OT and ICT. This new system redefines production — this is smart manufacturing.

Huawei integrates data to bring intelligence to every scenario where ICT becomes integral. Eventually, this convergence works with the cloud to enable integrated, data-driven management and decision-making. The model revolutionizes traditional manufacturing processes, paving the ideal path toward smart manufacturing.

Huawei has used this methodology to comprehensively transform our design and manufacturing processes for ICT infrastructure, mobile phones, and other products. We also widely apply AI. For example, Huawei's self-developed machine vision solution has been applied to 17 scenarios, such as appearance inspection and Optical Character Recognition (OCR). So far, we have deployed more than 600 solution systems in over 80 production lines.

Huawei's solutions have had remarkable impact. In the past, a production line for flagship mobile phones required 80 to 90 people. After introducing digital and intelligent solutions, the same line only needs 14 people and can output two mobile phones every 28 seconds. At Huawei's cloud data center in Langfang, the AI-based iCooling solution automatically optimizes energy efficiency, reducing the Power Usage Effectiveness (PUE) by 8% to 15%. It helps save 27 million kWh of electricity, which is equivalent to reducing 13,000 tons of carbon emissions.

Huawei has accumulated abundant experience by adopting digital and intelligent technologies. As we embrace the digital economy, we are actively sharing our experience and capabilities with industry customers and partners, helping them go digital.

So far, Huawei's digital solutions and services have been used by over 6000 manufacturers worldwide. We focus on manufacturing scenarios and use integrated ICT and OT to enable the digital transformation of the manufacturing sector. The benefits of our solutions are reflected in our customers' successes.

At SAIC Motor's Ningde Factory, Huawei's network connects over 500 in-process vehicles, 2000 smart terminals, and 10,000 sensors. The factory uses big data technologies and regression algorithms, which enable proactive risk warning for more than 1000 devices. This has helped reduce unplanned downtime by 20%. The factory now enjoys 48% more efficient production and can deliver vehicles 10% faster than before.

Chang'an Automobile has deployed Huawei's software development production line to quickly build applications. The factory uses the DevSecOps platform and follows industry best practices. Huawei has helped the automaker build a large-scale software test automation factory that is enabled by AI and runs around the clock. API quality is automatically monitored, and over 70% of API issues are automatically intercepted. Chang'an Automobile now enjoys ten times more efficient compilation and building processes along with 30% more efficient product delivery. Furthermore, the automaker has used the Huawei Cloud Astro low-code platform to quickly build a dozen new applications. Each application has taken just nine days to complete (instead of three months). Some examples include a marketing cloud map and production scheduling.

Another example is BYD's Changzhou factory that wanted to build a robust network to protect production from any interruptions. The network needed to deliver high reliability, low latency, a roaming handover latency below 100 ms, and a real-time communications latency below 20 ms. The network needed to be built quickly and allow for on-demand capacity expansion, high reliability, and simplified cabling. BYD used Huawei's Industry OptiX network to safeguard its production, because the optical network uses a green architecture, delivers high stability and reliability, and is flexible and efficient.

At Risen Energy's new energy factory, Huawei's industrial network is also making a difference. When producing circuit boards, each finished board needs to be photographed for inspection. Then, AI is used to intelligently filter and identify boards. There are nearly 100 inspection machines generating over 500 GB of data every day. Huawei's Industry OptiX network is capable of stably transmitting TBs of data. Even if a fault were to occur, rectification takes less than 50 ms. Ultimately, the network ensures that production lines run efficiently around the clock.

Moutai, one of China's largest producers of alcoholic beverages, is yet another enterprise benefiting from digital transformation with Huawei. Moutai and Huawei innovate together with a focus on solving common issues that affect spirit production. Through digital upgrades, Moutai is helping the whole industry transform and apply digital technologies for high-quality production.

These are just a few examples of how we help manufacturers transform. Huawei's solutions impact all aspects of the manufacturing process. This is largely thanks to our in-depth knowledge of ICT fundamental to the field, but also our ability to provide one of the best data foundations in the industry. We integrate computing, storage, and network devices, along with capitalizing on third-party design software to help manufacturers implement intelligent approaches through digital R&D.

Huawei doesn't achieve all this on our own. We are part of a robust ecosystem, which is why we develop open applications and methodologies. Our goal is to help everyone who cooperates with us to benefit from our innovations. We look forward to continued cooperation with industry partners, building an open, prosperous ecosystem to support the digital transformation of manufacturing in China and beyond. We hope to continue evolving as a trusted partner for the digital journey of manufacturers across various industries.

At Huawei's Manufacturing BU, our vision is to integrate OT and ICT, bring digital to every manufacturer, and establish a bright future for smart manufacturing. We are celebrating the first anniversary of the BU. Looking ahead, we will continue working with industry partners and delve even deeper into business scenarios to find the best digital solutions for the manufacturing sector. We hope to help the industry increase efficiency, improve quality, and achieve successful transformation.

Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the official policy, position, products, and technologies of Huawei Technologies Co., Ltd. If you need to learn more about the products and technologies of Huawei Technologies Co., Ltd., please visit our website at e.huawei.com or contact us.