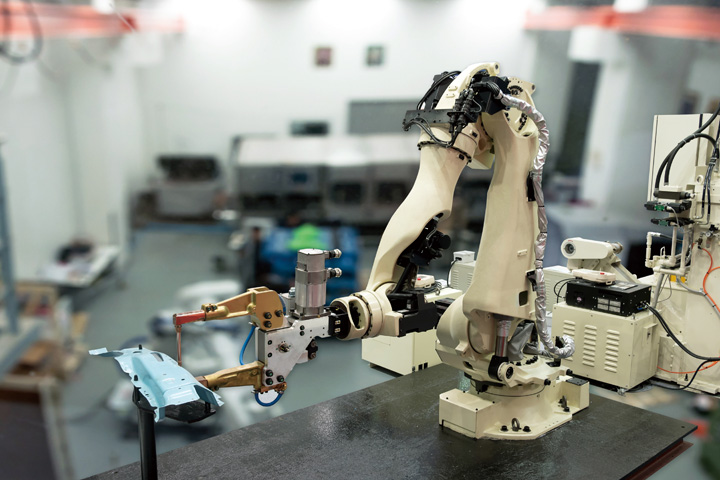

What Can YOUR Robot Do?

Produkty, Rozwiązania i usługi dla przedsiębiorstw

Our Earth faces increasingly grave environmental problems every day. Although more people have realized the significance of environmental protection and have chosen shared bicycles and electric cars as part of their low-carbon lifestyles, yet we still rely heavily on non-renewable energy such as petroleum. How much oil is left and how long will it last? According to estimates from conservative experts, the sustained oil reserves left may last only 30 to 40 years at present rates of consumption, and the next oil crisis may happen much sooner than expected. Governments and socially responsible companies worldwide are intensifying efforts to develop new energy and optimize technologies in order to improve the exploration, production, and utilization of energy such as oil.

Traditional technologies no longer meet the needs of enterprises. However, the advent of the Industry 4.0 era and the rise of smart manufacturing are bringing great hopes for energy conservation and emission reduction for the Earth.

Manufacturing is a traditional industry, and it covers oil refining, automobile manufacturing, appliance manufacturing, power grids, steel mills, chemical plants, and others. ICT systems in the manufacturing industry used to function as support systems, but now they are shifting to work as production systems. Smart manufacturing, which comprises smart factories, smart logistics, and smart services, has become a new direction for digital transformation of the manufacturing industry. The successful implementation of smart manufacturing is impossible without the support of leading new ICT technologies such as cloud computing, Big Data, the Internet of Things (IoT), and Artificial Intelligence (AI).

China Petrochemical Corporation (Sinopec Group) is China’s largest integrated energy and chemical enterprise. It ranked No. 3 on the 2017 Fortune Global 500 list. In 2013, Sinopec Group started its smart plant initiatives and selected its Yanshan, Maoming, Zhenhai, and Jiujiang companies as pilot smart factories.

Petro-CyberWorks Information Technology Company Limited (PCITC), a joint venture of Sinopec Group and Pacific Century CyberWorks Limited (PCCW), is the contractor for building these pilot smart factories. PCITC chose Huawei to make smart factories a reality. Big Data and machine learning technologies are used in smart factories. By facilitating the gathering of refining and production information, these technologies help streamline the chemical reaction processes during refining and production, and dynamically adjust the volumes of crude oil, fuels, and catalysts necessary for the refining process. The resulting benefits include optimal productivity at the lowest energy consumption, without compromising the oil quality. Additionally, experiential models for running equipment as well as Operations and Maintenance (O&M) are set up. These models help monitor equipment in real-time and anticipate the abnormal status of equipment to implement predictive maintenance, reduce O&M costs, and mitigate the risks of unplanned downtime.

At present, these four pilot smart factories report remarkable results, and constitute Smart Factory 1.0 in Sinopec Group. In the four pilot smart factories, the utilization rate of advanced control technology increases to over 90 percent; the automated production data collection rate reaches over 90 percent; and all pollution sources are automatically monitored. Production optimization used to be performed on a few processes and in offline mode, but now it is extended to all processes and conducted in online (in-service) mode. All these improvements increase labor productivity by over 10 percent and contribute to better quality and higher efficiency.

ICT has brought tangible benefits to companies in the petroleum and petrochemical industry and helps them maximize Return On Investment (ROI). Key benefits include better production-to-consumption ratios, higher oil recovery rates, lower operating costs, higher labor productivity, and long-time stable running of equipment.

Huawei, a leading global ICT solutions provider, offers a portfolio of market-proven solutions for the oil and gas sector, including digital oil-field, offshore oilfield communications, digital pipeline, smart refining, and intelligent sales solutions. These solutions are built upon Huawei’s extensive range of products such as wireless eLTE, IoT, KunLun servers, OceanStor 9000 high-end storage systems, High-Performance Computing (HPC), cloud data centers, public clouds, and cloud-enabled enterprise communications products. As of now, Huawei serves 60 percent of global Top 20 oil and gas companies, and has worked on more than 38,000 kilometers of oil and gas pipelines, which cover 41 percent of leading energy countries and regions.

With regard to Sinopec Group’s smart factory initiatives, Huawei joined hands with PCITC to provide real-time communications and computing capabilities as well as architecture-wide security capabilities.

Sinopec Jiujiang Company, a subsidiary of Sinopec Group, is used as an example. Sinopec Jiujiang Company is located on the northern bank of the Yangtze River and to the south of Mount Lushan. Every year, the company processes 10 million tons of crude oil and produces 300,000 tons of synthetic ammonia, 520,000 tons of urea, and 100,000 tons of polypropylene. The company has a total of 48 production units, most of which have industry-leading economic and technical specifications and outperform similar appliances in the industry.

Sinopec Jiujiang Company deployed Huawei’s eLTE Broadband Trunking solution to meet the company’s need for larger communications capacity and a multimedia trunking dispatch system. This solution helps the company easily deploy an audible and visual dispatch system. Additionally, this solution requires no wired transmission, greatly reducing the company’s investments.

Sinopec Jiujiang Company also chose Huawei’s OceanStor high-end storage system, ensuring that core business systems such as O&M and Enterprise Resource Planning (ERP) are stable. This new storage system is designed to be future-proof to support data center resource consolidation and service migration to the cloud in the future, which previously were impossible for original storage systems due to their limited scalability. Huawei’s high-end storage system also enables Sinopec Jiujiang Company to build a unified Office Automation (OA) platform that involves email, office applications, and portal subsystems, and also centrally stores data. Sinopec Jiujiang Company uses Huawei’s TE30 All-in-One HD Videoconferencing Endpoint system to enable video-assisted shift handover at work as well as internal and external communications — all greatly improve communication efficiency. With TE30 video conferencing, users can easily hold meetings through calls.

Sinopec Jiujiang Company adopted a series of advanced technologies and techniques, such as 4G wireless network applications, IoT-based smart warehouse, and a whole-process integrated optimization platform. All these implementations are first-of-a-kind in refineries.

In April 2017, PCITC and Huawei jointly announced a smart manufacturing platform, which is not only the two parties’ first significant joint innovation since they inked strategic partnerships, but also the core part of Smart Factory 2.0 within the Sinopec Group. This platform has eight major capabilities: Centralized integration, IoT access, IT management and control, optimization, shared services, data processing and analysis, and AI. The platform will become a ‘benchmarking operating system’ for smart manufacturing. This smart manufacturing platform also has integrated new ICT technologies such as cloud computing, the IoT, Big Data, Virtual Reality (VR), and machine learning. It is expected to become an industry-leading smart manufacturing platform in the process-centric industry. The eight capabilities of this platform are highlighted as follows:

Centralized integration: This platform consolidates smart factory data and information, enables centralized management and control of data assets, and allows effective integration with application systems.

IoT access: This platform provides ubiquitous, interoperable, smart converged communications services necessary for smart factories, and supports a wide range of service applications such as digital warehouse, tracking of hazardous chemicals, vibration and corrosion monitoring for key equipment, and environment monitoring.

IT management and control: This platform implements cloud management, security management, O&M management, and unified development; and allows for centralized management, monitoring, and resource allocation of cloud nodes.

Optimization: This platform comes with optimization tools and engines to streamline the entire production process, facilitate device operations, and improve energy efficiency.

Shared services: This platform centrally manages and controls business and technology service components, and provides shared cloud services to facilitate unified development.

Data processing and analysis: This platform unleashes the potential of Big Data and enables production exception analysis, equipment fault diagnosis, and product quality analysis.

Artificial intelligence: This AI-capable platform helps institutionalize rules, models, and knowledge, and creates a ‘smart brain’ for petrochemical plants using deeply learning and reasoning data.

Huawei and global partners join hands to launch a FusionCloud Smart Manufacturing solution which features efficient management, agile dispatching, and open architecture. This solution is a good choice for customers in the production and manufacturing industries, meeting their needs of industrial automation, information convergence, service-centric manufacturing, and flexible production.

This solution is the result of the collaborative efforts of Huawei and a group of industry partners such as SAP, Accenture, PCITC, Halliburton, and Forcecon. By enabling end-to-end management of the manufacturing processes that cover design, production, supply, logistics, and marketing, this full-stack cloud solution makes smart cloud-based and service-oriented manufacturing a reality. Big Data analytics and mining helps manufacturing companies resolve deep-rooted problems and pain points. All these benefits pave the way for building a cloud-enabled manufacturing platform characterized by intelligent management and unified architecture.

The day when we run out of oil will come sooner or later. However, we believe that leading new ICT technologies such as cloud computing and Big Data can play an active role for petrochemical enterprises as they help utilize energy in more efficient and environmentally friendly ways and continue to explore more green new energy sources.