[Barcelona, Spain, February 26, 2024] At MWC Barcelona 2024, Huawei launched the Intelligent Factory Solution, which was part of Huawei's Manufacturing and Large Enterprise Session on "Delve into Industries, Creating a Better, Greener, and Smarter Future". The session gathered industry leaders and experts to share the latest solutions and best practices in product R&D, production, and operation management, while also encouraging cooperation.

In today's world, digital technology is increasingly integrated into the real economy, with the focus of the integration shifting from consumer services to production. Digital technology is therefore no longer just seen as supplementary, but has become the engine driving innovation and development for enterprises. Three significant outcomes that will arise out of enterprise digitalization include: ubiquitous connections, service-based supply on demand, and platform-based efficient distribution.

Liu Chao, CEO of Huawei's Manufacturing and Large Enterprises Business Unit, said: "The integration of digital technology and the real economy is advancing. Huawei will continue to leverage technological innovation and industry know-how to provide intelligent products and solutions that cover the entire value chain of manufacturing enterprises. We will also collaborate with partners to serve end customers better." Liu continued to explain that Huawei aims to help enterprises upgrade their ICT infrastructure to accelerate product R&D and innovation, improve production efficiency while reducing costs, and ensure streamlined, sustainable enterprise operations.

Wang Zhiya, COO of Huawei's Manufacturing and Large Enterprises Business Unit, hosted the launch of the Intelligent Factory Solution. This solution adopts a technology architecture of "one cloud, one network, and one platform", which streamlines the engineering data flow, business information flow, and production process flow.

Specifically, "one network" integrates IP, industrial passive optical network (PON), and 5G technologies, making it possible to seamlessly connect numerous devices on a large scale across multiple scenarios. In addition, "one network" also bolsters the data collection efficiency to an industry-leading 1 million data points per second.

Furthermore, Huawei Cloud provides data and application enablement, as well as other services, to support intelligent applications such as advanced production scheduling and digital twins. This can help manufacturers shorten the order-to-delivery cycle while improving overall equipment effectiveness.

During the session, several guest speakers shared best practices from their companies. Regarding enterprise ICT infrastructure upgrades, Tamás Szabó, Officer of Data Center at BorsodChem, talked about his experience in building green data centers.

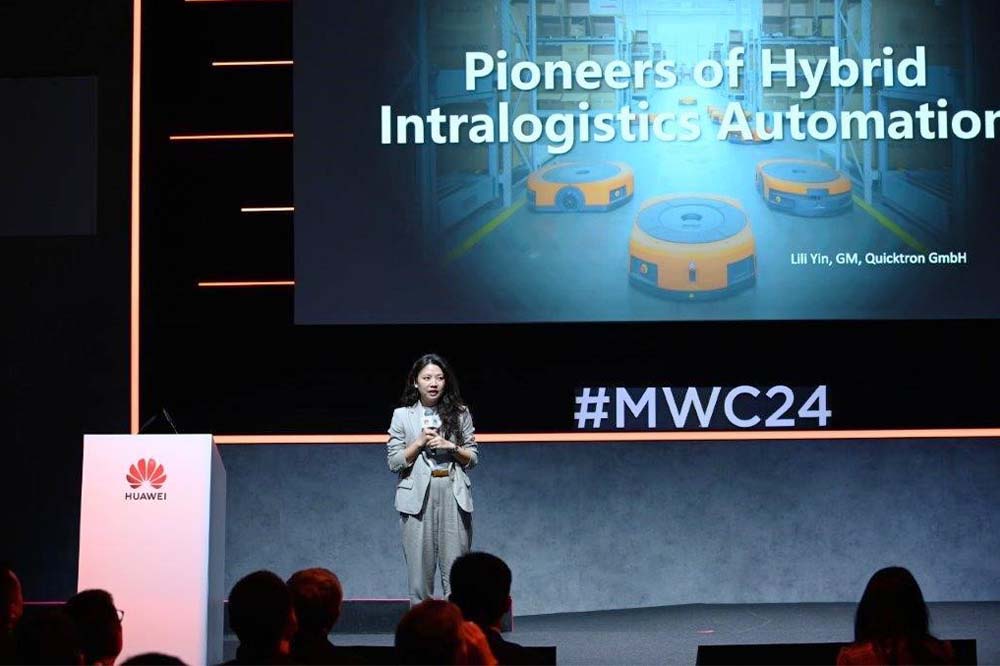

For intelligent enterprise applications, Lili Yin, General Manager of Europe at Quicktron Robotics, introduced how the Smart Logistics Operations System Solution jointly created with Huawei had made a difference. Ms. Yin shared reference project videos on quick warehouse AMRs powered by Huawei's AirEngine Wi-Fi 6 devices.

Huawei believes that through continuous interaction and exchange, along with joint efforts of the entire industry, enterprise digitalization and intelligence will continue to advance, ultimately bringing more potential for growth and a better future for the industry.

For more information, please visit: https://e.huawei.com/en/industries/manufacturing