This site uses cookies. By continuing to browse the site you are agreeing to our use of cookies. Read our privacy policy>

![]()

This site uses cookies. By continuing to browse the site you are agreeing to our use of cookies. Read our privacy policy>

![]()

Enterprise products, solutions & services

Energy is the foundation and driving force behind societal and technological development across the world, acting as the backbone of the economy, individual livelihoods, and human survival in general. In China, specifically, given coal is the most common energy source, the mining industry has prioritized making coal production digital and intelligent, to both maximize efficiency and mitigate environmental harm.

In order to find a more effective way to build intelligent coal mines, Huawei's Coal Mine Team has been working hard over recent years. Through joint developments with industry partners, they've reached the conclusion that the only way to efficiently achieve intelligent mine construction is to build an industrial Internet platform, based on unified architecture and standards, as well as reconstruct the information infrastructure of existing coal enterprises.

Intelligent coal mine development involves the integration of Information Technology (IT) and production technology, as well as three key transformations targeting the production mode, production factors, and producers. Achieving these transformations will facilitate the upgrade of the traditional production mode and make production management more efficient and safe.

Transforming the production mode prioritizes safety by minimizing — or potentially removing — the need for onsite personnel. With the shift from manual onsite operations to remote control and intelligent production, coal mining enterprises are greatly reducing workforce requirements, meaning fewer people are left unattended, or are needed for inspection and excavation . Moreover, such a shift sees the whole operation process become standardized and digitalized, greatly improving operational safety and efficiency.

Indeed, transforming production factors also prioritizes efficiency and safety. Alongside land, labor, capital, and technology, data has now become the fifth factor of production. For coal mines specifically, in order to ensure safety, improve processing efficiency, and gain maximum value out of raw coal, Deep Learning (DL) on massive mine data needs to be conducted to prevent gas leaks and other disasters, better manage raw material costs, and improve safety and production efficiency.

The transformation of producers involves modifying the responsibilities of workers, as well as enhancing their knowledge and experience of working with technology. The coal industry is now transforming into a high-tech industry. With the ongoing advancement of digitalization and intelligence, coal mining enterprise employees will more commonly work in remote centralized control offices, vastly improving their working environment.

Put simply, robust information infrastructure that integrates Information and Communications Technology (ICT) and coal production business flows, helps to tackle the five challenges and realize three transformations.

According to development guidelines and intelligent scoring acceptance standards documents, the implementation mode of intelligent coal mine development in China follows a top-down and bottom-up approach . Following this approach, data architecture, business architecture, and application architecture need to be determined from a top-level design through to implementation. Specifically, the construction of information infrastructure should be based on a unified platform, unified standards, and unified security.

With a key focus on ICT infrastructure — a small yet crucial part of intelligent mining solutions — Huawei uses information-based intelligent technologies to help enterprises and ecosystem partners improve their intelligence capabilities, jointly building coal mine architecture of the future.

Top-Level Architecture of Intelligent Mine Information Infrastructure

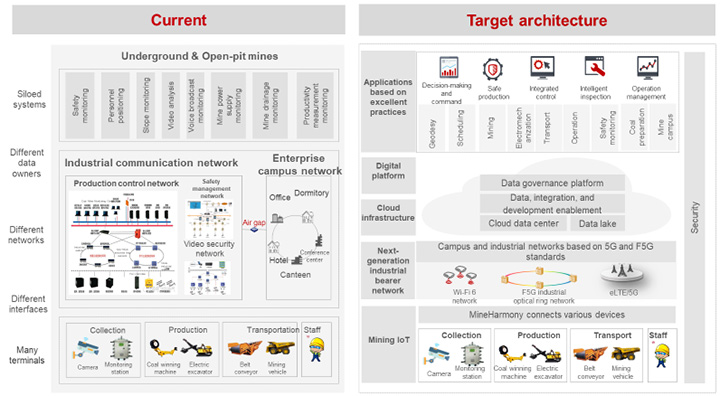

The essence of an intelligent mine is the industrial Internet: its core lies in establishing unified architecture and a standardized digital platform. Such a digital platform allows data assets to be deposited in mines, eliminating information silos. It also unifies interfaces and specifications to simplify platform construction, transforming intelligent mines from construction-driven to operations-driven. In addition, intelligent and automated applications — based on model algorithms, the cloud, and big data capabilities — are streamlined to achieve efficient and agile coal production.

From the perspective of industry development, digital platforms need five capabilities — application enablement, integration enablement, data enablement, Artificial Intelligence (AI) enablement, and development enablement — to help realize information and data convergence and sharing, maximizing the value of data. In Huawei's solution, these five capabilities are provided by the Relationship, Open, Multi-ecosystem, AnyConnect (ROMA) hybrid integration platform, the Data Lake Governance Center (DGC) , and the one-stop development platform for AI developers, ModelArts.

For example, after the digital platform accesses the data from a sensor device with its built-in Huawei Mine HarmonyOS , the ROMA component implements fast interconnection between the systems. ROMA connects Operational Technology (OT) and IT in the southbound direction, implementing simple interconnection and centralized data transfer.

The DGC component governs the data entering the lake. After governance, the data provides services for various application systems in the mine. In AI applications, the system uses the ModelArts component to perform AI training and modeling, such as automatic coal volume identification for transportation belts, foreign object identification, and integrated communication with one-pass and three-prevention s.

A unified Internet of Things (IoT) OS can replace OSs from multiple vendors, providing consistent access standards and specifications for a range of coal mine equipment and mass sensors. This helps unify interfaces and data formats, simplifying the interconnection of mining equipment, synchronizing collaboration between devices, supporting cross-system data exchange, and enabling intelligent development and application release.

Mine HarmonyOS features three core values: the Internet of Everything (IoE), unified data standards, and industry security. By unifying device communication protocols and standardizing device protocol specifications, interworking between intelligent coal mine devices is achieved. For example, distributed soft bus technology supports multi-communication channel backup, which implements link routing and protocol selection insensitive . In addition, data standards — interface formats, data specifications, and dater layer protocols — are unified, eliminating data silos and making cross-system intelligence possible. In addition, thanks to the autonomous capabilities of Mine HarmonyOS, industry security is ensured.

With the advancement of coal mine informatization, enterprises working in the field have faced severe security threats in recent years. Protecting data, of course, has now become hugely important. To cope with cyber security risks, China has issued a series of security laws and regulations. Grade II protection has now become the basic requirement of intelligent coal mines, with Grade III protection set to become the trend in the foreseeable future.

Mine HarmonyOS complies with, indeed enhances, the technical and service security standards of the coal mine industry. It facilitates the construction of a security moat for equipment systems and security standards for operations. System security teams can also use technical attack defense, quick recovery, and improved protection capabilities to unify device security hardening services, shortening the security upgrade period of device vendors.

Based on its rich experience in data security protection, Huawei provides a one-stop graded security solution for the coal mining industry, covering the entire lifecycle, from system grading, system archiving, construction, and rectification to grade assessment, supervision, and inspection, alongside End to End consulting services (E2E).

For construction procedures, although the path of three unifications is clearly visible, the goal cannot be achieved overnight, and needs constant iteration. Intelligent construction can only be carried out in stages according to the objective conditions and actual requirements of different coal mines. Making such iterations avoids unnecessary changes and excessive investment.

As the development of intelligent coal mines continues to accelerate rapidly, one trend is becoming clearer and clearer: top-level designs based on unified architecture and standards. Such unified information infrastructure not only facilitates the organic integration of multiple advanced technologies involved in coal development and production processes, but also facilitates rapid data entry into the lake.

The aim is to work with industrial applications and equipment partners to streamline cross-system service data flows and build digital twins. Based on an open platform and architecture, ecosystem partners perform agile iteration and innovation, to quickly meet the needs of coal mining enterprises and improve industry informatization and intelligence. On this basis, the intelligent construction of coal mines will quickly progress, realizing the future of intelligent, green , safe mines with little to no onsite manpower required.