PEA (Thailand) Collaborates with Huawei to Accelerate Intelligent Power Substation Development

Produits, solutions et services pour les entreprises

Akıllı Telefonlar, Bilgisayar&Tabletler, Giyilebilirler ve Daha Fazlası

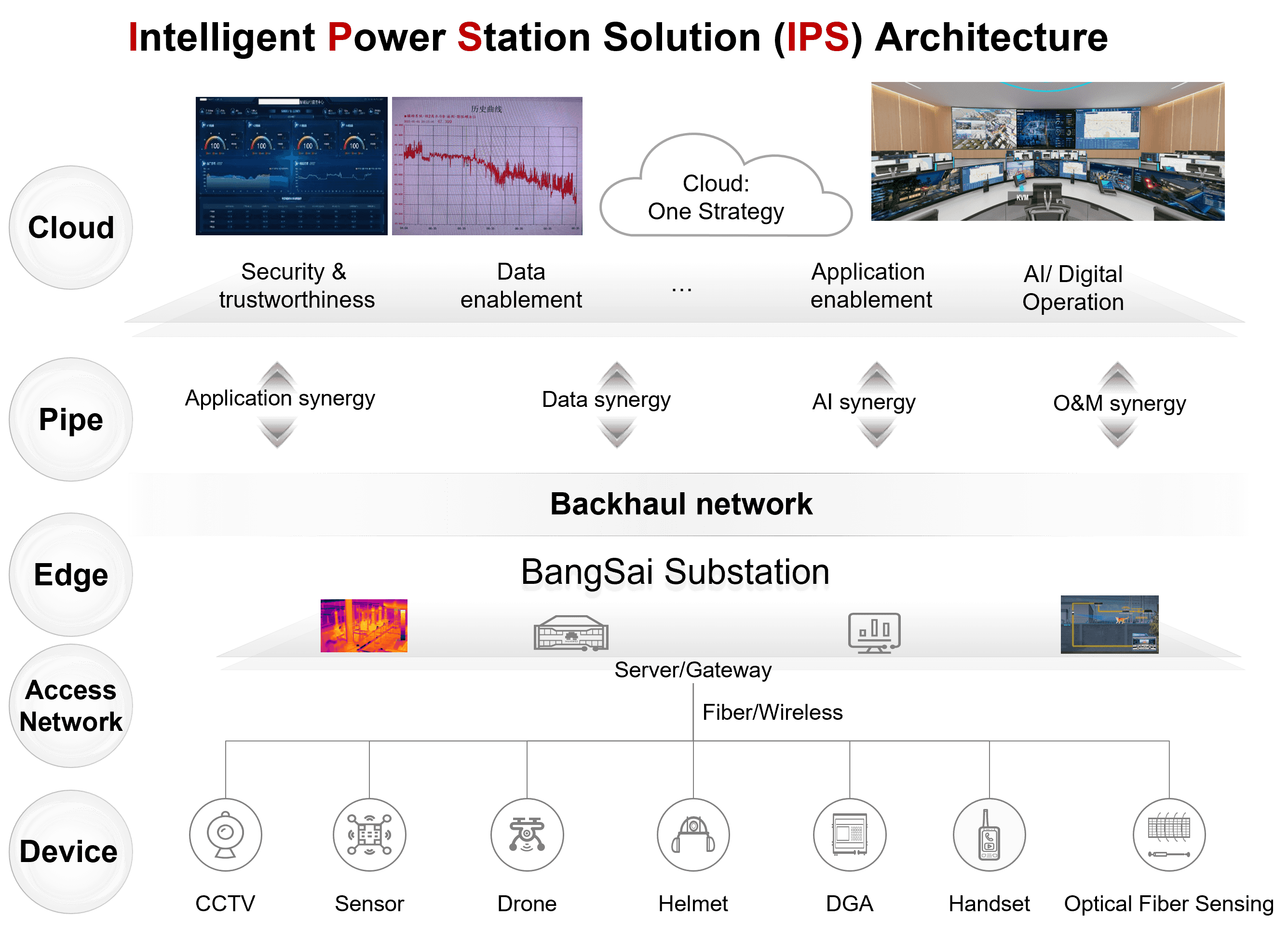

To promote the deep integration of digital technologies with power scenarios, Huawei Digital Site provides PEA with two product solutions: digital substation and perimeter protection substation, helping achieve full transparency of site resources, status, and operations, improving the efficiency and safety management level of power grid operations, and ensuring the safe and stable operation of substations.

Amid the global energy transition and the accelerating digitalization of power grids, the power industry is undergoing a shift from "reactive maintenance" to "proactive prevention." As Thailand's core distribution operator, PEA serves over one-third of the country's population across all 74 provinces. To meet the rapidly growing demand for electricity, PEA has partnered with Huawei to drive digital upgrades at its substations using AI and IoT technologies, enhancing the operational management efficiency of substations and ensuring their safe and stable operation.

1.Enhanced Risk Identification

Provide all-weather, high-precision identification of potential safety hazards at substation equipment and unauthorized intrusions at the perimeter to reduce false alarms and missed detections.

2.Improved Inspection Efficiency

With multiple business systems, traditional manual inspections are time-consuming and labor-intensive. There is a need to achieve automated and large-scale route inspections.

3.Building a Secure and Integrated Network

The lack of a trusted integrated network limits the development of new services, creating an urgent need for a power transmission and transformation network that is highly reliable, secure, and offers large bandwidth.

1.Perimeter Protection: All-Weather Digital Defense Line

By deploying Huawei‘s perimeter protection substation solution, which utilizes fiber optic sensing technology combined with Huawei’s AI model algorithms, intrusions by people or animals can be automatically detected. The system quickly triggers cameras to capture images, and maintenance personnel can remotely confirm the alerts, shifting from “reactive response ” to “proactive warning ” This provides 24/7 monitoring, building an all-weather digital security defense line.

2.Innovative Intelligent Inspection and Operation & Maintenance Model

By deploying Huawei's digital substation solution, which incorporates multi-scenario AI inspection algorithms, CV large models combined with historical data analysis, and cloud-edge collaboration technologies, the system supports automatic identification of meter readings and early warning for transformer oil leakage. This enables remote real-time management of equipment operating status, achieving “AI-based precise identification and real-time alarm warnings,” with faults detected and addressed within one minute.

3.Comprehensive Connectivity · Unifying Sensing Networks

Through the integrated deployment of wired and wireless networks, as well as broadband and narrowband networks at the same site, the solution simplifies network management at stations. It also features high bandwidth and low power consumption, enabling more efficient IoT data transmission and ensuring reliable support for existing production services while facilitating rapid integration of new services.

1.Enhance safety capabilities

Prevent theft at substations and reduce the risk of electric shock accidents among personnel.

2.Improve inspection efficiency

Online inspections allow real-time acquisition of equipment status, reducing the frequency of on-site visits and decreasing the workload of inspections.

3.Increase equipment availability

Real-time assessment of equipment health status, reducing the cycle time for detecting and handling equipment failures.