This site uses cookies. By continuing to browse the site you are agreeing to our use of cookies. Read our privacy policy>

![]()

This site uses cookies. By continuing to browse the site you are agreeing to our use of cookies. Read our privacy policy>

![]()

Продукты, решения и услуги для предприятий

Смартфоны, ПК и планшеты, носимые устройства и многое другое

[Shanghai, China, September 20, 2023] During HUAWEI CONNECT 2023, Huawei held the Global Manufacturing and Large Enterprise Summit themed Bring Intelligence into Manufacturing. At the event, Huawei released a series of solutions and consulting services, which integrate Huawei's reference architecture for the intelligent transformation of industries into the processes and business scenarios of manufacturers and other large enterprises. The summit brought together over 700 enterprise customers, technical experts, partners, and representatives of industry alliances to discuss how to use AI and other digital technologies to accelerate the intelligent transformation of the manufacturing industry.

As global efforts are being made to promote the in-depth integration of digital and real economies, digital technologies such as cloud computing, big data, the industrial Internet, and AI are becoming increasingly pervasive. "Huawei has been innovating in products and solutions, accumulating experience and practices as a manufacturing enterprise, and keeping to the concept of collaboration for shared success," said Liu Chao, CEO of Huawei's Manufacturing and Large Enterprises BU. "We are working with manufacturing and large enterprise customers to bring intelligent transformation to the next level, from intelligent ICT infrastructure, to intelligent business scenarios including R&D, production, supply, and sales, and now to intelligent products."

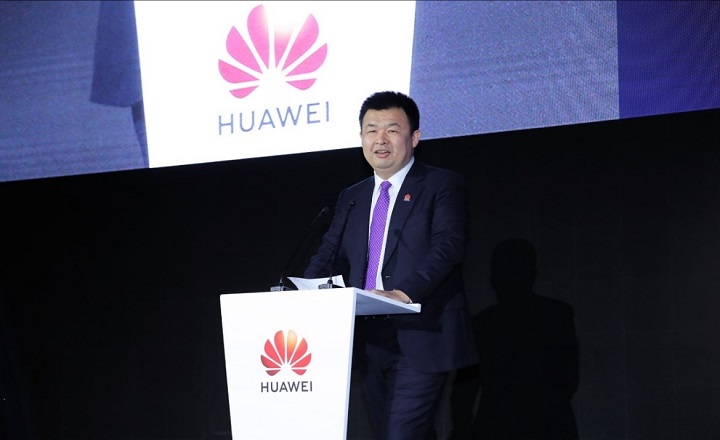

Wang Zhiya, COO of Huawei's Manufacturing and Large Enterprises BU, introduced Huawei' intelligent solutions and consulting services using examples of the company's own practices in different business scenarios.

• Huawei's R&D cloud solution helps the company double R&D service volumes and improve operational efficiency by over 50% while cutting down on the actual R&D resources needed by 40%. The solution also enhances application security and enables minute-level software vulnerability detection.

• For production, Huawei has developed an upgraded Intelligent Factory 2.0 solution. The solution uses a one cloud, one network, one platform, and N applications architecture and incorporates intelligent applications to deliver full-stack AI, including intelligent computing, Kunpeng, and Huawei Cloud Pangu models. It improves the training and deployment of AI algorithms in certain scenarios like factory quality inspection and production scheduling, helping factories advance intelligence.

• Huawei also proposed the full-stack industrial AI platform solution. The open architecture of this solution allows users to integrate Huawei's computing power, algorithms, and intelligent platform into their products. This facilitates intelligent product innovation in automotive, software, home appliance, and many other industries.

At the summit, Tao Jingwen, CIO of Huawei, spoke as a special guest. "Demands for ensured business continuity drive enterprises to embark on a new journey of digital, intelligent innovation," said Tao in his speech titled Digital Platform Accelerates Intelligent Enterprise Upgrades. "We need to do things right the first time and avoid repeated investment. This requires modernized applications to accelerate services." Tao also explained how AI foundation models can be used to drive real-time intelligence, and how innovation in system engineering is important to building first-class products. In addition, a digital platform–based strategy is critical for enterprises to gain advantages in information, decision-making, and operations in the digital world. These will help enterprises achieve intelligent upgrades.

Wang Rui, Vice President of iFLYTEK, believes that AI will be the core engine of the industrial Internet. For example, iFLYTEK empowered its "Antelope" Industrial Internet Platform with its AI model, SparkDesk, which resulted in a new industrial model. This new model can power business domains from R&D, production, and supply to marketing, service, and management. Wang said that industrial AI is destined to start new trends in industrial Internet development.

Wu Kezhi, General Manager of Chang'an Automobile's Yubei Factory, summarized from the company's practical experience that consistent, standardized, complete, and unified service data is not only the foundation for OT-IT integration but also the prerequisite for digital twin simulation. In the intelligent factory of Chang'an Automobile, millions of data collection points have been deployed to collect data from over 12,000 machines in seven workshops across six processes. Ten subject domains have been designed (such as production, planning, and logistics), involving 91 service objects and upwards of 3000 logical entities. Through data governance, the factory has truly integrated OT and IT. The digital platform allows the automaker to work with partners to innovate in a range of scenarios with intelligence, including intelligent production scheduling, quality issue tracing, as well as digital twin and factory simulation.

Xiao Yi, Director of the Ecosystem Solution Dept of Huawei Cloud, discussed in her speech the present and future of industrial digitalization. According to her observations, as industry data and reality are increasingly integrated, industrial digitalization is reaching new heights. As one of the pioneers in digital, intelligent transformation, Huawei keeps integrating data of three core service flows, namely, product lifecycle management, production process, and value creation. It uses the FusionPlant industrial Internet platform to promote the digitalization of industrial equipment, cloud adoption of industrial software, value mining of industrial data, and full connectivity of industrial networks. With technology as the base and intelligence as the core, Huawei has built a model development pipeline to accelerate the integration of data and reality. This will in turn accelerate intelligent upgrades.

As time goes on, Huawei's solutions for manufacturing and large enterprises will continue to help customers improve management experience and facilitate the digital transformation of the manufacturing industry.

For more information, visit: https://e.huawei.com/en/industries/manufacturing