This site uses cookies. By continuing to browse the site you are agreeing to our use of cookies. Read our privacy policy>

![]()

This site uses cookies. By continuing to browse the site you are agreeing to our use of cookies. Read our privacy policy>

![]()

Продукты, решения и услуги для предприятий

Смартфоны, ПК и планшеты, носимые устройства и многое другое

Currently, industrial intelligence is developing at an ever-increasing rate. Industrial enterprises need robust information infrastructure in order to deeply integrate innovative ICT and production service flows. Underpinning industrial Internet construction, industrial networks are also continuously developing and evolving. Huawei's highly reliable FTTM solution — based on the fifth-generation fixed network (F5G) — injects new impetus into this field.

Industrial networks are always pursuing high performance, reliability, flexibility, and security. With constant industrial upgrades, traditional industrial networks face the following challenges that prevent them from meeting the ever-growing requirements for intelligent construction:

• Traditional networks are not reliable in production environments with extreme ambient temperatures and EMI. For example, high-voltage and high-power motors in battery production or automobile stamping workshops frequently start and stop, causing conducted electromagnetic interference transmitted along cables and radiated electromagnetic interference transmitted in space. Even Ethernet cables with additional shielding layers do not have sufficient anti-interference capabilities in such scenarios.

• Traditional networks cannot resolve the network congestion that occurs due to the vast numbers of terminals connecting to the network. As a result, latency cannot be guaranteed, which poses a risk to industrial production. For example, in an automobile manufacturing production line, one automobile can be assembled in 60 seconds under normal conditions. If the production line is interrupted for 30 minutes, a loss of US$1 million will be incurred.

In addition, the complex networking of traditional networks causes a high risk of network storms, while capacity expansion is difficult. The large number of network cables also complicate installation, deployment, and management, hindering the intelligent industrial development.

Optical communications technology has advantages such as large bandwidth and low loss, and is an important foundation of modern communications. In 2022, driven by a series of policies, the optical communications industry achieved significant progress. China has built the world's largest and most complete optical communications industry system, leading the industry in certain key technologies such as optical communications devices, optical modules, fibers, and optical cables.

In recent years, Huawei has applied the F5G technology to industrial scenarios and made key innovations in media, network architecture, management, and O&M.

• Regarding media innovation, F5G replaces traditional copper cables with optical fibers for transmission. Fibers are made of silicon dioxide (glass), which is stable and resistant to corrosion and electromagnetic interference. The bandwidth of optical fibers can be smoothly evolved to 50 Gbit/s or even 100 Gbit/s, ensuring your network is future-proofed in preparation of future upgrades. In practice, fibers do not need to be replaced for at least 10 years, reducing the TCO by 30%.

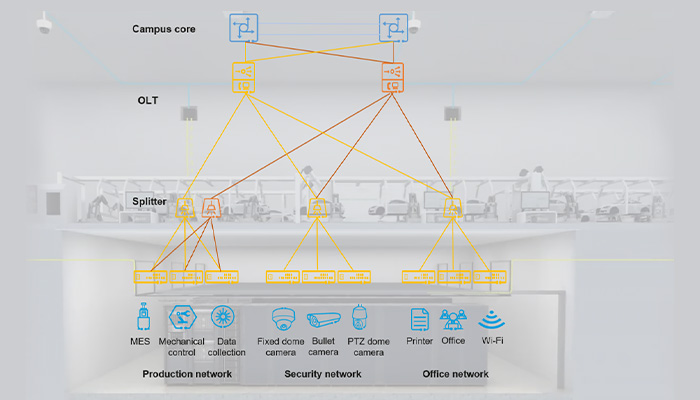

• When it comes to architecture innovation, the 2 layers architecture supports point-to-multipoint (P2MP) transmission. With the passive ODN, the active OLT is deployed in the data center and ONUs are close to access information points, delivering a transmission distance of up to 40 km. Better yet, no cabinets need to be deployed in the workshop, improving the overall deployment efficiency by 30% and easily carrying services on the ultra-long production line network.

• In terms of O&M innovation, the production, office, and security networks are integrated and carried by a single optical network. Passive components require no O&M and the fault rate is low, while ONUs are plug-and-play upon power-on. What's more, Network-wide devices are centrally managed by eSight, achieving visualized E2E O&M. Network topologies and link node statuses are displayed, and alarms can be detected in real time. In addition, the intelligent optical path diagnosis can quickly locate fiber faults, improving O&M efficiency by 60% and enabling one person to manage the entire factory network.

With the rapid development of optical fiber communications technologies and the maturity of the industry chain, Huawei's FTTM solution is undergoing a series of upgrades in 2023. The upgrades include zero packet loss, deterministic low latency, and ultra-long chain networking, which help build a lossless industrial optical network and start a new trend in the industry.

• Industrial production requires high network reliability, which is affected by packet loss. Huawei's FTTM solution supports dual fed and selective receiving, ensuring zero packet loss during link switching. By using a star network architecture, this solution also ensures zero packet loss on other nodes upon single-node failure or when a network node is added or deleted.

• In addition to zero packet loss, the lossless industrial optical network uses time division multiplexing (TDM) and hard isolation technologies to dynamically schedule network bandwidth and prevent network congestion.

• In addition, Huawei's innovative optical regeneration unit (ORU) can achieve 120 km coverage and support 128-level cascading. This makes it perfect for scenarios such as highways, tunnels, and corridors, where information points are distributed in a chain manner and cover a long distance.

Located in Shiyan, China, Dongfeng Machine Tool Plant (Dongfeng Machine for short) is taking advantage of new opportunities in the digital economy. In particular, they are leveraging F5G all-optical network technology to deepen the integration of ICT technologies such as F5G with the manufacturing industry. This serves to support network-based, digital, and intelligent transformation of smart equipment industrial campuses.

"The smart upgrade of factories depends on a solid network foundation", said by Wang Zhongliang, Director of Digital Intelligent Technology Business Dept of Dongfeng Machine. He pointed out that the traditional network architecture is limited by the transmission bandwidth and distance of copper cables. As a new ICT technology based on fiber connections, F5G is green, simplified, stable, reliable, and flexible, becoming an important infrastructure for smart factories and workshops as we move towards smart manufacturing.

On Dongfeng Machine's backbone campus network, Huawei EA5800 series OLTs carry GPON network services. In workshops, industrial ONUs are deployed to provide highly reliable access solutions for factory production and office.

In a factory, many automatic production devices need to be controlled in a unified manner. This, however, poses high requirements on the bandwidth and reliability of the fixed network. This is where the F5G passive optical network comes in, as it features high bandwidth, massive connections, and high reliability. For example, in production, remote monitoring and precise control requires all-optical networks, which have low latency and low packet loss rate, to improve production precision and ensure reliable data transmission.

As we move towards smart manufacturing, future-oriented network infrastructure is a must. The innovative advantages of the Huawei FTTM solution in architecture, evolution, and O&M not only provide high-quality network connections for various industrial scenarios to improve production efficiency, but also promote energy saving and green production for sustainable development. Since 2020, the Huawei FTTM solution has undergone rapid development, seeing wide use in industries such as factories, subways, highways, ports, electric power, intersections, and mining. In the future, as its applications are further enhanced, it will surely play an even more important role.

Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the official policy, position, products, and technologies of Huawei Technologies Co., Ltd. If you need to learn more about the products and technologies of Huawei Technologies Co., Ltd., please visit our website at e.huawei.com or contact us.