Enterprise products, solutions & services

The digital transformation of large enterprises, particularly those operating in the financial and government sectors, has seen data become more profuse and increasingly vital, to such an extent that enterprises and governments are now driving Data Center (DC) construction. Reports estimate that the number of DCs will quadruple by 2025, with the Compound Annual Growth Rate (CAGR) of data traffic between DCs reaching approximately 48%. This growth of data traffic between DCs will double the cost of private line leasing, dramatically outstripping enterprise budgets, suppressing service bandwidth, and restricting the digital transformation of enterprises. In addition to these challenges, other problems — such as the uncontrollable response times of leased private-line services and unstable network quality — are becoming more and more significant. To overcome them, enterprises are leaning toward leasing optical fibers to build their own Data Center Interconnect (DCI) networks. However, before embarking on such a project to self-build a DCI network, several factors need to be taken into account.

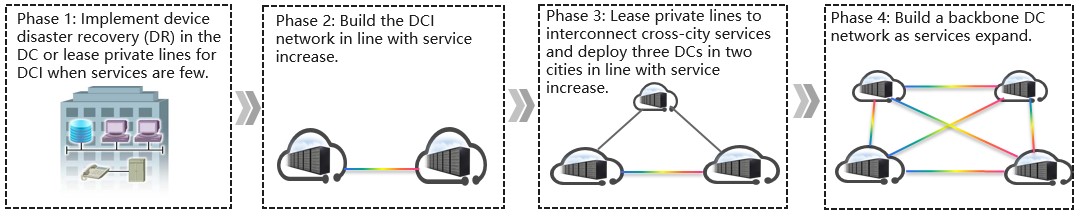

The four phases of enterprise DC development.

There are two solutions for a self-built DCI network. The first is direct fiber connection: in other words, one fiber per service. In this instance, through a pair of fibers, a switch's 10 GE port can reach a transmission distance of 80 km, satisfying transmission requirements between intra-city DCs. Here, DCI network deployment is very simple since the initial service volume is small. However, fiber resources are limited and bandwidth utilization is too low, causing fibers, leasing, and maintenance costs to multiply as services surge. In addition, transmission distance is limited as switch ports speed up.

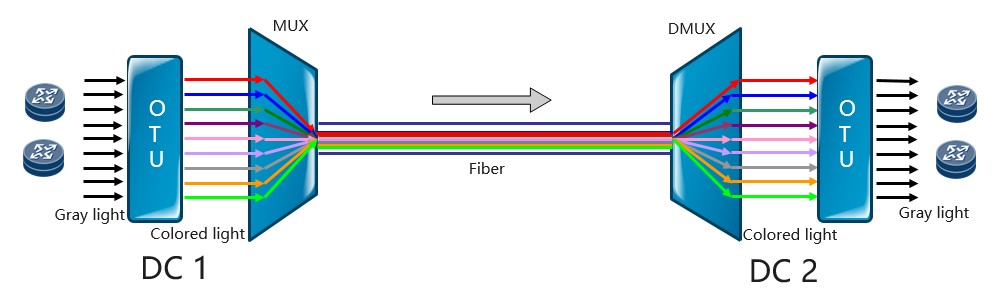

A second solution turns to Wavelength Division Multiplexing (WDM) interconnection. Using wavelength multiplexing and high-performance transmission technologies, a single optical fiber can provide a capacity of 10+ Gbit/s to 10+ Tbit/s, covering thousands of kilometers and satisfying the bandwidth requirements of enterprises for the next five to ten years. Compared to leased private lines and direct fiber connection, WDM interconnection allows capacity expansion with the simple addition of ports or service boards. And the rise in service volumes and system capacity actually leads to a lower cost per bit for a self-built DCI network. Indeed, such an investment will level out within six months for bandwidths exceeding 40 Gbit/s, compared with expensive leased private lines. In simple terms, the higher the bandwidth the faster the investment will level out. Through a one-hop site connection, low latency and stable transmission can be realized. Accordingly, more and more large enterprises, especially those working in the finance and government sectors, are turning to WDM devices to build DCI networks.

Basic principle diagram of WDM.

For those working in the finance and government sectors, and for large enterprises and non-profit organizations alike, the reliability and security of DCI networks — for Disaster Recovery (DR) and backup — is key. In terms of reliability, WDM is a well-established technology that has been operational for over 30 years: it is fully developed, regardless of lower-layer protocols and upper layer management. WDM itself emphasizes the application of physics and chipset technology, which places high requirements on customers' expertise. Indeed, many enterprise customers lack the necessary technical understanding of WDM. Consequently, choosing a qualified device supplier — especially one with R&D capabilities and a large number of successful cases on a live network — becomes vital for enterprise customers, in what will become a long-term cooperation. Devices must support redundancy protection for key components, such as system control boards, power supplies, and fans, to ensure devices run stably. It is recommended that two pairs of optical fibers be leased on the network side to provide 1 + 1 protection for devices. In terms of security, WDM uses wavelength hard pipe isolation technology, which greatly improves service isolation and transmission security, compared with transparently transmitting Ethernet data flows. Furthermore, WDM devices provide AES256 encryption functionality at the physical layer to encrypt services on a single port, ensuring data security.

WDM DC DR and backup networking.

Enterprises are naturally profit-driven, valuing Return On Investment (ROI) over other factors. However, reducing Total Cost of Ownership (TCO) is becoming increasingly important for enterprises who build their own DCI networks. A major factor driving DCI network development is the demand for fast service rollout in the Internet era, which places higher requirements on rapid delivery. Traditional WDM devices are designed to the telecommunications room standards of carriers, using a 48 V DC power supply. However, the number of power supply ports varies with devices, with cabinets either 300 mm or 600 mm deep (complying with ETSI standards), with top to bottom, or left to right air exhausts. The complexity of traditional WDM devices is evident in their structure (which includes service boards and multiple types of optical-layer boards), installation procedures, and fiber connections. Fiber connection faults are therefore difficult to locate: specialized engineers are required to locate faults, posing even further technical requirements. To ensure optimal delivery, a pre-installation site survey must be carried out, meaning that the delivery period of traditional WDM devices usually spans several weeks or even months. A DC's overall design is based on the IT equipment room, with unified specifications and standards. Yet, when building a DCI network, customers can choose WDM devices that are suitable for DC installation, without requiring site survey or equipment room reconstruction. Here Huawei offers some suggestions. Firstly, choose devices that have high single-fiber capacity and integration to save on fiber leasing, reduce space requirements, and lower power consumption. Second, co-deploy electrical-layer and optical-layer devices in the same platform to reduce device types. Finally, simplify optical-layer boards. For example, multiplexer/demultiplexer boards, Optical Amplifier (OA) boards, and optical supervisory boards need to be integrated to reduce board types, decrease internal fiber connections, and lower the technical requirements for construction, shortening the delivery period, and reducing TCO.

A WDM system places high technical requirements on Operations and Maintenance (O&M) personnel. Following decades of technical innovation, WDM devices are now equipped with diverse service fault detection capabilities. Yet, WDM devices still consist of many fault detection items, analog parameters, and information, which can put pressure on O&M. Most commissioning engineers in DCs are IT personnel, and the team is likely responsible for commissioning various devices from multiple vendors and in multiple domains. In this context, O&M for WDM devices has become a growing concern that cannot be solved by merely adding more staff: a learning period is required, increasing the subsequent cost of manpower. To reduce O&M costs, WDM devices are increasingly focusing on automation and intelligence. For example, with a built-in and installation-free WebGUI, hardware installation personnel can configure basic device information, and check fiber connections and device running status during device installation, avoiding the need for multiple site visits, boosting overall deployment efficiency. Through intelligent means, maintenance efficiency can be improved. The digital optical layer requires zero commissioning, freeing operators from complex analog parameters. Secondly, services are automatically adapted to achieve automatic service provisioning, with zero configuration. Finally, comprehensive network alarm information means that faults can be located and root causes can be analyzed quickly, simplifying maintenance and enabling IT personnel to more easily deploy and maintain the network.

In recent years, WDM devices designed for customer self-built DCI networks have emerged in the market. For enterprise IT personnel, the simplified design of one-click deployment lowers WDM expertise requirements. Introducing Artificial Intelligence (AI) technology into O&M will facilitate easier DCI network construction for enterprises.