FTTM Helps FAW Build Technology Innovation Space

This site uses cookies. By continuing to browse the site you are agreeing to our use of cookies. Read our privacy policy>

![]()

Enterprise products, solutions & services

The network is the foundation of smart manufacturing. As smart manufacturing becomes more widespread, a growing number of industries and campuses are going digital, networked, and intelligent. In this process, the FTTM (fiber to the machine) solution, which applies the fifth-generation fixed network (F5G) technology, is widely adopted in the construction of infrastructure networks.

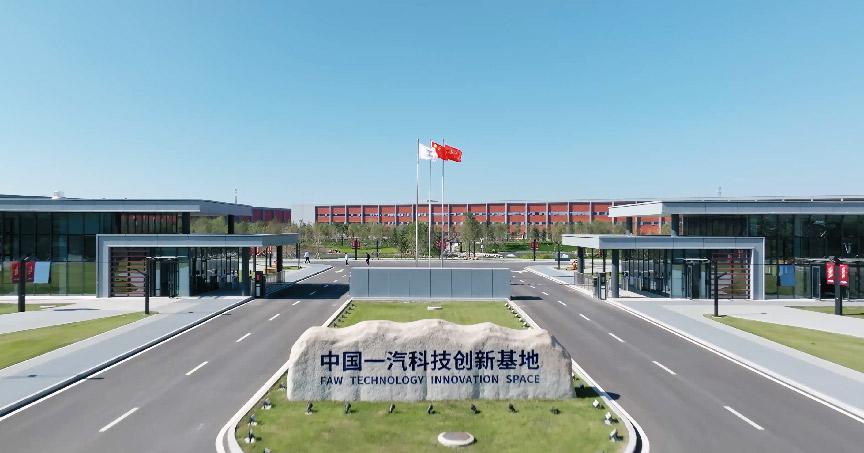

First Automobile Works (FAW), a Chinese automobile manufacturer, applied the Huawei FTTM solution in the network construction for its Technology Innovation Space. The solution features ultra-high bandwidth, deterministic latency, and flexible capacity expansion, creating a powerful network to support the technology innovation and testing in the campus.

The FAW Technology Innovation Space is designed to be a smart industrial campus, and the infrastructure network is the base for connecting everything. With F5G, the FTTM solution can fully support new energy vehicle (NEV) development and testing, promoting the technology innovation of China FAW.

During digital transformation, the industrial Internet is integral to realizing smart manufacturing.

A wide range of digital applications can be seen through the automobile manufacturing industry, which was one of the first industries to undergo digital transformation. All areas of the industry have been upgraded, from product development, design verification, and manufacturing, to quality control and process improvement.

The automobile industry is now the largest platform of consumer intelligent products and computing. With the emergence of NEVs, automobile products become more intelligent, connected, and service-oriented. Digital transformation is driving the automobile industry into a brand new era.

After three years of construction, the FAW Technology Innovation Space officially opened in July 2023. Consisting of Qi'an, Qiyuan, and Qizhi innovation zones, the space performs passive security tests and verifications, covering the entire simulation toolchain from models to real vehicles. It also supports environmental testing of NEV electronic control, high-speed in-vehicle network, man-machine interaction, and as vehicle parts.

The space is designed to provide world-class testing capabilities for NEVs and intelligent connected vehicles. It is established to support the technology innovation of China FAW brands such as Hongqi by providing security performance tests. With this space, FAW has formed comprehensive capabilities in passenger vehicle development and testing.

FAW Technology Innovation Space uses many systems in its labs, including data collection, test and precision control, high-speed camera, and intelligent OA systems. Each of these systems requires a network with high-bandwidth and deterministic latency to ensure that concurrent services are transmitted with high speed, reliability, and security.

For example, the profusion of high-speed cameras in the labs can generate up to 1000 frames per second, while bursts of 500M may occur on the network.

Traditional switches adopt the first in, first out (FIFO) principle, which can result in unstable latency during traffic bursts, thereby affecting services such as data collection and auto control in the labs. Moreover, traditional networks use one "pipe" to transmit services, leading to bandwidth contention. As it is difficult to accurately evaluate the metrics on traditional networks, the network performance cannot be guaranteed.

Routine O&M is also a major consideration in network construction for the FAW Technology Innovation Space. During daily lab operations, information points are dynamically adjusted and added on demand. As such, the network needs to support fast capacity expansion and fault demarcation.

Traditional networks are costly both to deploy and maintain. What's worse, they do not offer the high reliability and deterministic latency required by the labs. Such shortcomings mean that traditional networks are not suitable for the FAW Technology Innovation Space.

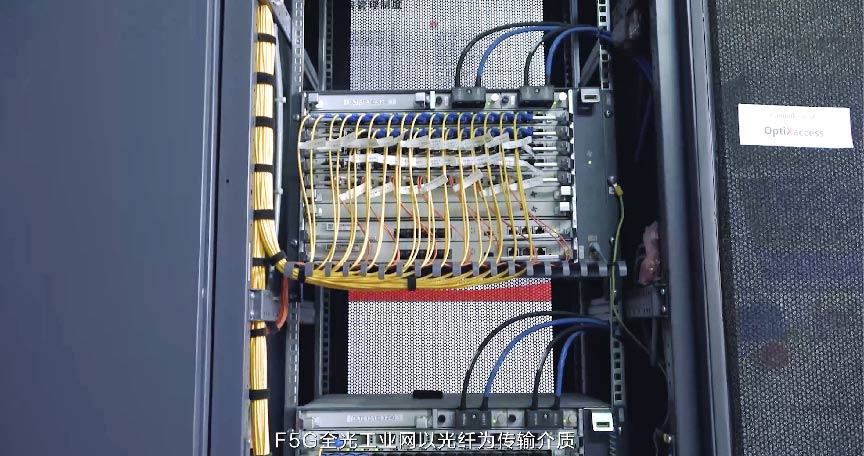

The Huawei FTTM solution had drawn the attention of China FAW even before the Technology Innovation Space construction had commenced. It is now used as the network solution for phase 2 of the construction project. The FTTM network uses fiber as the transmission medium, due to its immunity to electromagnetic interference and corrosion, as well as its long service life of more than 10 years.

The solution replaces the traditional three-layer network architecture with a two-layer P2MP architecture, and active components with passive components. In this solution, ONUs can be flexibly deployed across the campus, and 10G high-density fibers are extended to each room, desktop, lab, and machine, carrying all applications on a single optical network and delivering premium performance.

Tests at the innovation space generate torrents of data every day. This is why network security and reliability are so crucial. The FTTM solution enables end-to-end hard isolation, allowing the system to dynamically adjust the service bandwidth and expand capacity. A powerful network analyzer is also provided to visualize many network metrics and meet the network requirements for automobile development and tests. More importantly, the technology is highly reliable.

For example, the battery lab needs to detect terminal data such as the voltage, current, temperature, capacity, and internal resistance, and upload it to the cloud data management platform in real time. But none of this would be possible without massive data collection, model trainings, and various data analysis tasks, requiring millisecond-level latency and real-time response without service interruption.

The FTTM network running in the labs has realized end-to-end dual-link protection and fast switchover within 30 ms. Both data collection and precision tests are running smoothly on the network.

As new technologies and services emerge, the FTTM network can support XGS-PON and smooth evolution to 50G PON by reusing network infrastructure. In this way, cables in the factories can be used for at least 10 years, reducing the TCO by 30%.

In terms of routine O&M, network topologies are visible on the NMS. Fibers are routed to desktops and workstations, enabling automatic fault detection and reducing the time required to locate faults from hours to minutes. All ONUs in the factories are centrally managed by an optical line terminal (OLT), so that one person can manage the entire campus network, significantly reducing the O&M cost.

So far, the FTTM network has been deployed to carry services including tests, precision control, high-speed camera, and intelligent OA at the FAW Technology Innovation Space. As the campus digital transformation continues, the FTTM network will unleash more potential in applications such as office-to-cloud, diverse IoT services, and 4K video security.

Fueled by the Huawei FTTM solution, the FAW Technology Innovation Space has created a campus network that features ultra-high bandwidth, reliable and lossless services, intelligent O&M, and smooth evolution, connecting humans, machines, and things. The solution helps China FAW implement its "All in new energy" strategy and embrace the trend of smart manufacturing.

The manufacturing industry transformation should be centered around technologies and devices to upgrade production lines, workshops, factories, and the supply chain. The ultimate goal for the industry is to go digital and intelligent, connected by a smart manufacturing system that integrates the virtual and physical world, and is dynamic, secure, and efficient.

The FTTM network, featuring deterministic experience, ultra-high bandwidth, security, reliability, and energy efficiency, has been widely adopted in more than 20 industries, including education, healthcare, energy, transportation, and manufacturing, and has redefined their capabilities.

Digital transformation is still ongoing. Smart manufacturing represents the ever-increasing requirement of manufacturers for data connectivity and convergence. The FTTM solution can help unleash the potential of digital development by providing stable connectivity and excellent network performance.